Easy Cash $$$ Do a simple CAD Design for 3D Printing - 31/03/2020 15:48 EDT

- Status: Closed

- Prize: €100

- Entries Received: 31

- Winner: sami3008

Contest Brief

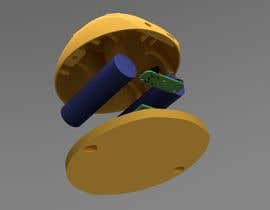

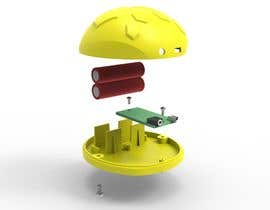

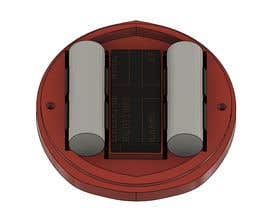

Design a simple circuit board holder and battery holder to be 3D printed with the base.

The circuit board is L= 64 mm * W= 27 mm * H= 12 mm

There will be connected wires on the top of the circuit board

We have two batteries each with the dimensions below:

The battery’s dimensions are L=67 mm * D = 20 mm.

Where L is length, W is the width H is the Height and D is the diameter respectively.

I have included 2 mm on each side in the dimensions for perfect fit.

Bonus Point the minimalistic design.

Bonus Points if the Circuit Board and batteries can be secure in place

Bonus Point is the design does not take too much space

Bonus point if the overall design does not use too much materials

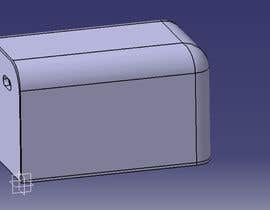

Included is also the design of the Top case.

Bonus Points if you can improve on this design.

On the front of the Top case is the holes for the mini USB and a female audio jack.

The diameter of the female audio jack hole is 6 mm. The distance from the perimeter of the female audio jack to the perimeter of the hole of the mini USB is 14 mm.

The diameter of the mini USB hole is 10 mm * 4 mm

I want a CAD and 3D printing designer to join my team.

Note:

The overall Case design I have shared with you is 15 percent larger than required.

Please refer to images and designs.

Recommended Skills

Employer Feedback

“Patient, enjoys learning and very engaged. Mohamed provided me with very detailed and high quality feedback throughout the project. The results were everything I could have asked for... Thank very much Mohamed.”

![]() IcoNNZ, Ireland.

IcoNNZ, Ireland.

Top entries from this contest

-

tricker3006 Indonesia

-

kudratreyimbayew Turkey

-

devswarnakar India

-

lecorbusier1234 Colombia

-

lecorbusier1234 Colombia

-

ceanet Brazil

-

jnpulkit India

-

ceanet Brazil

-

prasadpvc92 India

-

jnpulkit India

-

Narutolalang Vietnam

-

lecorbusier1234 Colombia

-

DC47 India

-

mridulmaheshwari India

-

jaylangdon Australia

-

Adre4 Poland

Public Clarification Board

How to get started with contests

-

Post Your Contest Quick and easy

-

Get Tons of Entries From around the world

-

Award the best entry Download the files - Easy!